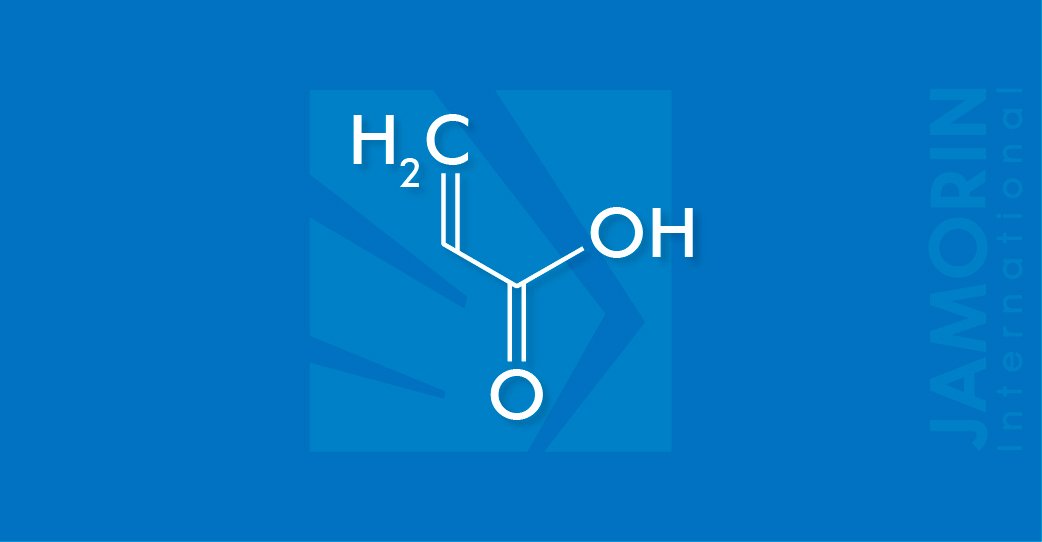

C3H4O2

min. 99.9%

C3H4O2

min. 99.9%

Acrylic Acid Glacial (GAA)

Acrylic Acid Glacial (GAA) is an unsaturated monocarboxylic acid. Effective as a vinyl compound and as a carboxylic acid. Acrylic Acid Glacial (GAA) is easily subjected to radial (co)polymerization and addition reactions. Copolymers of Acrylic Acid Glacial (GAK) can be prepared with (meth)acrylic esters, acrylonitrile, vinyl acetate, vinyl chloride, styrene, and other monomers by all known radical polymerization technologies.

Acrylic Acid Glacial (GAA) is used to produce various esters from esterification reactions with alcohol.

Product Type: Acrylate Monomer

Features & Benefits:

- Hydrophilicity

- Water solubility

- Adhesion

- Any required rheological properties

Applications areas:

- Polyacrylic acid and copolymers of Acrylic Acid Glacial are used in the pulp and paper, paint and varnish, textile industries, the production of detergents, ceramics, perfumes, and cosmetics, in water treatment, in medicine and oil production as binders, film-forming agents, thickeners, scale inhibitors, adhesives, drilling mud modifiers, modifiers drugs, etc. The scope of their application is constantly expanding.

- Acrylic acid Glacial (GAA) is used to synthesize its esters and salts.

- Acrylic acid Glacial (GAA) is used in the production of superabsorbents.

It is applied in the production of:

- Acrylic & Waterborne dispersions

- Industrial & Architectural coatings

- Paints & Varnishes

- Textiles

- Pulp & Paper

- Paper & Leather coatings

- Wood & Metal coatings

- Film-forming agents

- Thickeners

- Scale inhibitors

- Adhesives

- Drilling mud modifiers

- Inks, caulks & sealants

- Many of the other industries…

Chemical Properties:

-

Puritymin. 99.9 %

-

Water contentmax. 0.15 %

-

Color APHAmax. 20

Physical Properties:

-

AppearanceClear, colorless

-

Physical formLiquid at >13 °C

-

OdorPungent

-

Molecular weight72.1 g/mol

-

Density1.051 g/cm3 at 25 °C

-

Boiling Point141,6 (142) °C

-

Freezing Pointapprox. 13 °C

-

Melting Point13 °C

-

Viscosity1.3 mPa · s at 20°C

-

Vapor Pointat 20 °C / at 40 °C: 3.8 mbar / 13.5 mbar

-

pH1.0 - 2 at 500 g/L

To avoid polymerization, Acrylic Acid Glacial (GAA) should always be stored in air and not under inert gases. For the stabilizer to function effectively, oxygen is required. Acrylic Acid Glacial (GAA) should be stored at a temperature of 15°C to 25°C. For long-term storage of more than 4 weeks, it is recommended to replenish the content of dissolved oxygen. Under these conditions, the storage stability of one year can be expected. In order to minimize the likelihood of excess storage, the storage procedure must strictly follow the "first-come-first-go" principle. To prevent freezing, the temperature of acrylic acid should never drop below 15°C. Improper thawing can lead to severe polymerization. Do not attempt to defrost frozen or partially frozen acrylic acid unless you have obtained prior permission from your supplier. It is strongly recommended that emergency stabilization systems be installed. This can help prevent the polymerization of the material in case of overheating, contamination, or other unforeseen events, although this cannot replace appropriate preventative measures. During transportation, the temperature of Acrylic Acid Glacial (GAA) should be maintained in the range of 15-25°C. Acrylic Acid Glacial (GAA), packed in barrels, is transported in covered wagons, cars that provide storage conditions along the route. At temperatures above 130 ° C, transportation of acrylic acid in barrels by open road transport is allowed, provided that the product is protected from exposure to sunlight and precipitation. Acrylic Acid Glacial (GAA) drum packaging is carried out on flat pallets. Means of fastening pallets - steel wire, steel or polymer tape, manufactured according to the normative-technical documentation, approved in the prescribed manner. Barrels should be filled to 0.9 volumes and sealed. Bulk Acrylic Acid Glacial (GAA) in railway tanks is transported in accordance with the rules for the transport of goods operating on this type of transport. Acrylic Acid Glacial (GAA), poured into tank containers, is transported by rail, road and sea in accordance with the rules for the transport of goods operating on this type of transport.

Storage & Handling:

To avoid polymerization, Acrylic Acid Glacial (GAA) should always be stored in air and not under inert gases. For the stabilizer to function effectively, oxygen is required. Acrylic Acid Glacial (GAA) should be stored at a temperature of 15°C to 25°C. For long-term storage of more than 4 weeks, it is recommended to replenish the content of dissolved oxygen. Under these conditions, the storage stability of one year can be expected. In order to minimize the likelihood of excess storage, the storage procedure must strictly follow the "first-come-first-go" principle. To prevent freezing, the temperature of acrylic acid should never drop below 15°C. Improper thawing can lead to severe polymerization. Do not attempt to defrost frozen or partially frozen acrylic acid unless you have obtained prior permission from your supplier. It is strongly recommended that emergency stabilization systems be installed. This can help prevent the polymerization of the material in case of overheating, contamination, or other unforeseen events, although this cannot replace appropriate preventative measures. During transportation, the temperature of Acrylic Acid Glacial (GAA) should be maintained in the range of 15-25°C. Acrylic Acid Glacial (GAA), packed in barrels, is transported in covered wagons, cars that provide storage conditions along the route. At temperatures above 130 ° C, transportation of acrylic acid in barrels by open road transport is allowed, provided that the product is protected from exposure to sunlight and precipitation. Acrylic Acid Glacial (GAA) drum packaging is carried out on flat pallets. Means of fastening pallets - steel wire, steel or polymer tape, manufactured according to the normative-technical documentation, approved in the prescribed manner. Barrels should be filled to 0.9 volumes and sealed. Bulk Acrylic Acid Glacial (GAA) in railway tanks is transported in accordance with the rules for the transport of goods operating on this type of transport. Acrylic Acid Glacial (GAA), poured into tank containers, is transported by rail, road and sea in accordance with the rules for the transport of goods operating on this type of transport.

Acrylic Acid Glacial (GAA) is a flammable and combustible liquid, it is easily polymerized by heat and initiators. Hazard Class 8. The polymerization reaction proceeds with the release of heat, while the reaction self-accelerates, the temperature and vapor pressure increase sharply, which leads to the explosion of the tank, barrel, container, tank. The occurrence of a fire and explosion may be facilitated by the presence of an open-source of fire, smoking, local overheating, and violations during the conduct of hot work. The flash point is 48°C (in a closed crucible) and 54°C (in an open crucible). The auto-ignition temperature is 440°C. The flash point is 67°C. The temperature limits of flame spread are 48-93°C. The concentration limits of flame spread, volume fraction of 3-17%. The carbon dioxide, powder fire extinguishers are used to extinguish a fire. Acrylic Acid Glacial (GAA) is very irritating to the skin. Irritating to the mucous membranes of the eyes (irritant threshold 0.04 mg / l). Eye contact causes severe burns to the cornea of the eye and can cause permanent damage. Inhalation of vapors can cause irritation of the respiratory tract, headache, with high concentrations or exposure - pulmonary edema. Although odor does not mean any health hazard, air monitoring is required. The maximum permissible concentration in the air is 5 mg / m³.

The data presented here are based on current knowledge and experience. Given the many factors that can affect the processing and use of the product, these data do not free consumers from the need to conduct their own tests and samples. Also, these data do not imply a guarantee of any specific properties or suitability of the product for a particular application. Any descriptions, drawings, photographs, data, ratios, weights, etc. presented here. subject to change without prior notice and do not constitute the contractual quality of the product. The end-user of the product is required to comply with all property rights and existing laws, as well as legal standards.