C7H12O2

min. 99.5%

C7H12O2

min. 99.5%

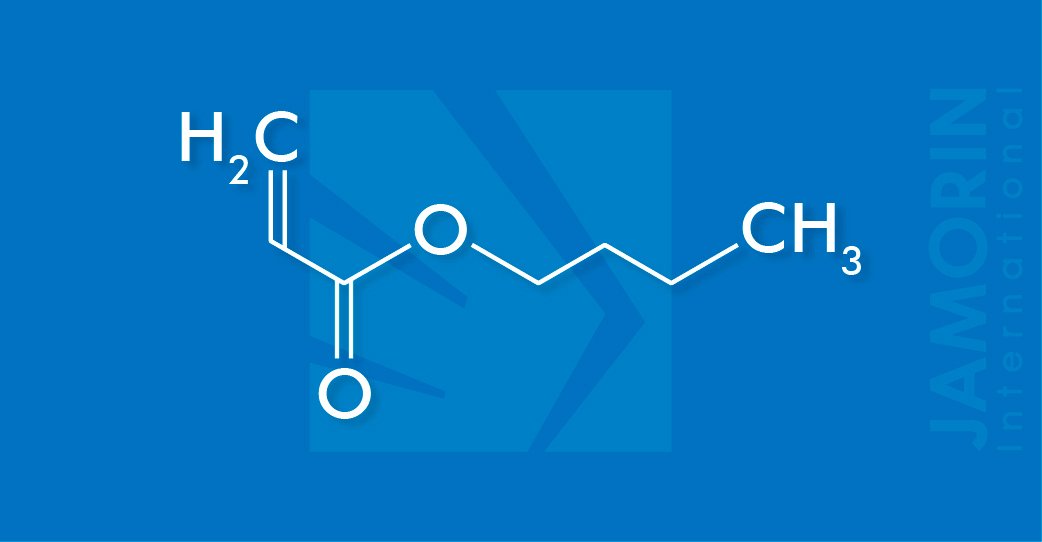

Butyl Acrylate (BA)

Butyl Acrylate (BA) is an ester of Acrylic acid and is used as a raw material component in the synthesis of polymers. Butyl Acrylate (BA) is a monofunctional monomer consisting of an acrylate group with a characteristic high reactivity and a cyclic hydrophobic group. Copolymers of Butyl Acrylate (BA) can be prepared with (met)acrylic acid and its salts, amides, and esters, and with methacrylates, acrylonitrile, maleic acid esters, vinyl acetate, vinyl chloride, vinylidene chloride, styrene, butadiene, unsaturated polyesters and drying oils, etc.

Butyl Acrylate (BA) is a very useful feedstock for chemical syntheses because it readily undergoes addition reactions with a wide variety of organic and inorganic compounds.

Product Type: Acrylate Monomer

Features & Benefits:

- Hydrophobicity

- Adhesion

- Water resistance

- Low-temperature performance

- Strength & durability

- Flexibility

- Viscosity

- Weatherability

Characteristics:

- Butyl Acrylate (BA) is also used in adhesive and as a polymeric plasticizer for harder resins. Butyl Acrylate (BA) can be used to balance as such key properties as the hardness and softness, tackiness, low-temperature flexibility, strength and durability, and a lot of the others.

Applications areas:

- Butyl Acrylate (BA) is used in the production of organic glass and as a comonomer in the synthesis of acrylic dispersions used in adhesives, binders, impregnating compositions in the leather, printing, paint, varnish, pulp and paper, and other industries.

It is applied in the production of:

- Acrylic & Water-borne dispersions

- Water-borne industrial & architectural paints

- Industrial & Architectural coatings

- Varnishes

- Textiles

- Pulp & Paper

- Paper & Leather coatings

- Wood & Metal coatings

- Adhesives

- Inks, caulks & sealants

- Many of the other industries…

Chemical Properties:

-

Puritymin. 99.5%

-

Acid Valuemax. 0.01%

-

Water contentmax. 0.05%

-

Color APHAmax. 10

Physical Properties:

-

AppearanceClear, colorless

-

Physical formLiquid

-

OdorPungent

-

Molecular weight128.2 g/mol

-

Tg– 55 °C

-

Density0.898 g/cm3 at 20 °C

-

Boiling Pointapprox. 148 °C

-

Freezing Pointapprox. – 64 °C

-

Melting Pointapprox. – 64 °C

-

Viscosity0.92 mPa · s at 20 °C

-

Vapor Point5.4 mbar at 20 °C

-

pHn/a

In order to prevent polymerization, butyl acrylate must always be stored under air, and never under inert gases. The presence of oxygen is required for the stabilizer to function effectively. It has to contain a stabilizer, and the storage temperature must not exceed 35 °C. Under these conditions, a storage stability of one year can be expected. In order to minimize the likelihood of over storage, the storage procedure should strictly follow the “first-in-first-out” principle. For extended storage periods over 4 weeks, it is advisable to replenish the dissolved oxygen content. Stainless steel or aluminum should be used for tanks and pipes. Although Butyl acrylate does not corrode carbon steel, there is a risk of contamination if corrosion does occur. Regulations for the storage of flammable liquids must be observed (explosion-proof electrical equipment, vented tanks with flame arresters, etc.). Storage tanks, pumps, and pipes must be earthed. For more detailed information please consult also the brochure “SAFE HANDLING AND STORAGE OF ACRYLIC ESTERS” of EBAM.

Storage & Handling:

In order to prevent polymerization, butyl acrylate must always be stored under air, and never under inert gases. The presence of oxygen is required for the stabilizer to function effectively. It has to contain a stabilizer, and the storage temperature must not exceed 35 °C. Under these conditions, a storage stability of one year can be expected. In order to minimize the likelihood of over storage, the storage procedure should strictly follow the “first-in-first-out” principle. For extended storage periods over 4 weeks, it is advisable to replenish the dissolved oxygen content. Stainless steel or aluminum should be used for tanks and pipes. Although Butyl acrylate does not corrode carbon steel, there is a risk of contamination if corrosion does occur. Regulations for the storage of flammable liquids must be observed (explosion-proof electrical equipment, vented tanks with flame arresters, etc.). Storage tanks, pumps, and pipes must be earthed. For more detailed information please consult also the brochure “SAFE HANDLING AND STORAGE OF ACRYLIC ESTERS” of EBAM.

Butyl Acrylate (BA) is a flammable, combustible liquid. Hazard class 3. Auto-ignition temperature 280°C. Ignition temperature 510С. The flash point is 38°C (in a closed crucible), 48°C (in an open crucible). The temperature limits of the ignition of a flame 37-81°C. The concentration limits of flame spread 1.2-7.4% vol. Butyl Acrylate (BA) has a general toxic effect, irritates the skin, mucous membranes, upper respiratory tract, digestive tract, causes long-term contact burns, inhalation of excess vapor - pulmonary edema; MPC in the air of the working zone 30/10 mg / m3.

The data contained in this publication are based on our current knowledge and experience. In view of the many factors that may affect the processing and application of our product, these data do not relieve processors from carrying out their own investigations and tests; neither do these data imply any guarantee of certain properties, nor the suitability of the product for a specific purpose. Any descriptions, drawings, photographs, data, proportions, weights, etc. given herein may change without prior information and do not constitute the agreed contractual quality of the product. It is the responsibility of the recipient of our products to ensure that any proprietary rights and existing laws and legislation are observed.