C70H138O27

C72H142O27

60 ± 3 %

C70H138O27

C72H142O27

60 ± 3 %

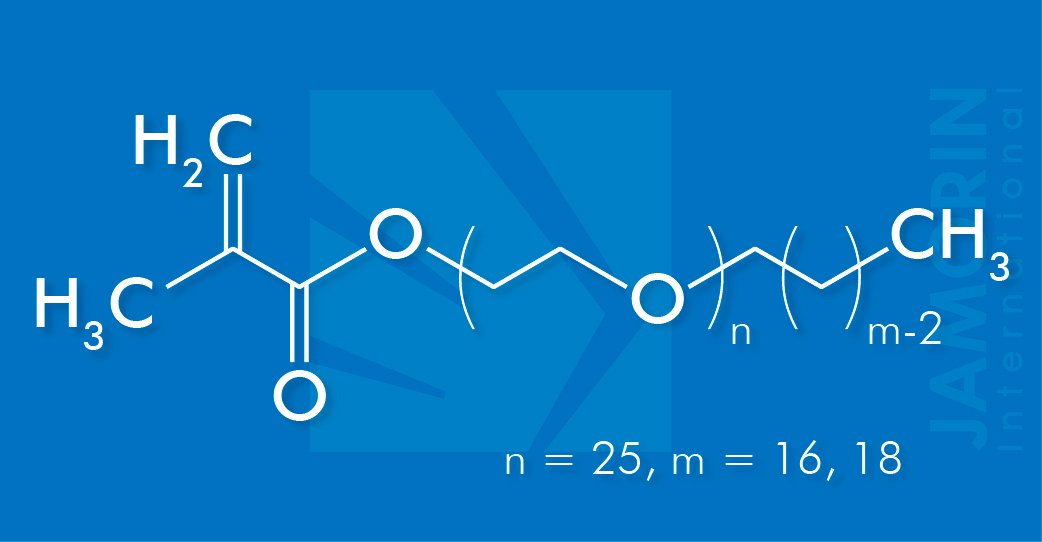

Stearyl Polyethyleneglycol Methacrylate 1100 (SPEGMA 1100)

Stearyl Polyethyleneglycol Methacrylate 1100 (SPEGMA 1100) is an ester of Methacrylic Acid and is used as a raw material component in the synthesis of polymers. Stearyl Polyethyleneglycol Methacrylate 1100 (SPEGMA 1100) is a monofunctional monomer consisting of a methacrylate group with a characteristic high reactivity and a cyclic hydrophobic group. Stearyl Polyethyleneglycol Methacrylate 1100 (SPEGMA 1100) forms homopolymers and copolymers. Copolymers of Stearyl Polyethyleneglycol Methacrylate 1100 (SPEGMA 1100) can be prepared with (meth)acrylic acid and its salts, amides, and esters, and with (meth)acrylates, acrylonitrile, maleic acid esters, vinyl acetate, vinyl chloride, vinylidene chloride, styrene, butadiene, unsaturated polyesters and drying oils, etc.

Stearyl Polyethyleneglycol Methacrylate 1100 (SPEGMA 1100) easily entering into the reaction of accession with a wide range of organic and inorganic substances, is used for the synthesis of organic low molecular weight substances.

Product Type: PEG Methacrylate Monomer

Features & Benefits:

- Hydrophobicity

- Hydrophilicity

- Rheology modification (associative thickening)

- Dispersibility

- Low (Tg) glass transition temperature

- Low volatility due to high molecular weight

Characteristics:

- Stearyl Polyethyleneglycol Methacrylate 1100 (SPEGMA 1100) is a structure-activity relationship in associative thickening: in alkaline soluble emulsions/polymers, small amounts of hydrophobic comonomers like SPEGMA interact with each other and create thickening when interacting with other monomer chains.

Applications areas:

- Stearyl Polyethyleneglycol Methacrylate 1100 (SPEGMA 1100) is used in the preparation of solid polymers, acrylic dispersions, and polymer solutions, which are used in various industries.

It is applied in the production of:

- Coatings

- Pulp & Paper

- Adhesives

- Personal care

- Oilfield chemicals

- Life Science

Chemical Properties:

-

Purity60 ± 3 %

-

Acid Value20 ± 2 %

-

Water content20 ± 2 %

-

Color APHAmax. 100

Physical Properties:

-

AppearanceClear, colorless

-

Physical formLiquid

-

Molecular weight1411.9 g/mol / 1439.9 g/mol

-

Tg–58 °C

-

Density1.05 g/cm3 at 20 °C

-

Boiling Pointn/a

-

Melting Point0.9 °C

-

Vapor Pointn/a

-

pH3 – 4.5

To avoid polymerization, Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) should always be stored in air and not under inert gases. For the effective functioning of the stabilizer, the presence of oxygen is necessary. Freezing of Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) leads to the separation of monomer and inhibitor. In addition, it is especially it is important to replenish dissolved oxygen after melting the drum material before use. Dissolved Oxygen Replenishment and Mixing MEHQ's monomer can be made using a palette or a drum toggle switch. The melting process requires a temperature of 20 °C or higher, but not more than 35 °C as the heating temperature. Heating the product indoors at a temperature of 20-25 °C for several days is the preferred option. Alternatively, if faster melting is required, heating cabinets that use hot water or hot oil are the preferred device for defrosting Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100), as this avoids hot spots. Local hot spots above 35 ° C can lead to premature aging of the material. Product temperatures above 45 °C may lead to the polymerization of the monomer. During storage in the form of molten liquid, it is advisable to replenish the content of dissolved oxygen weekly. Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) must contain a stabilizer and the storage temperature must not exceed 20 °C to prevent premature deterioration. If the above conditions are met, then during storage, you can expect the storage stability of Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) for 6 months.

Storage & Handling:

To avoid polymerization, Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) should always be stored in air and not under inert gases. For the effective functioning of the stabilizer, the presence of oxygen is necessary. Freezing of Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) leads to the separation of monomer and inhibitor. In addition, it is especially it is important to replenish dissolved oxygen after melting the drum material before use. Dissolved Oxygen Replenishment and Mixing MEHQ's monomer can be made using a palette or a drum toggle switch. The melting process requires a temperature of 20 °C or higher, but not more than 35 °C as the heating temperature. Heating the product indoors at a temperature of 20-25 °C for several days is the preferred option. Alternatively, if faster melting is required, heating cabinets that use hot water or hot oil are the preferred device for defrosting Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100), as this avoids hot spots. Local hot spots above 35 ° C can lead to premature aging of the material. Product temperatures above 45 °C may lead to the polymerization of the monomer. During storage in the form of molten liquid, it is advisable to replenish the content of dissolved oxygen weekly. Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) must contain a stabilizer and the storage temperature must not exceed 20 °C to prevent premature deterioration. If the above conditions are met, then during storage, you can expect the storage stability of Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) for 6 months.

A Safety Data Sheet has been compiled for Stearyl Polyethyleneglycol Methacrylate 1100 (SPEGMA 1100) that contains up-to-date information on questions relevant to safety. When working with Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100), the sanitary rules for organizing technological processes and hygienic requirements for production equipment must be strictly observed. All types of work with Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) should be carried out in rooms equipped with general supply and exhaust ventilation. It is not allowed to carry out work in these rooms using an open fire. Those working with Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) must be provided with special clothing and personal protective equipment in accordance with GOST 12.4.034. In the event of a fire, it is necessary to use fire extinguishers OP-5, OVP-100 felt, sand, asbestos cloth. Stearylpolyethyleneglycol Methacrylate 1100 (SPEGMA 1100) poured onto solid ground should be covered with sand.

The data presented here are based on current knowledge and experience. Given the many factors that can affect the processing and use of the product, this data does not free consumers from the need to conduct their own tests and samples. Also, these data do not imply a guarantee of any specific properties or suitability of the product for a particular application. Any descriptions, drawings, photographs, data, ratios, weights, etc. presented here. subject to change without prior notice and do not constitute the contractual quality of the product. The end-user of the product is required to comply with all property rights and existing laws, as well as legal standards.