C7H12O3

min. 97.0%

C7H12O3

min. 97.0%

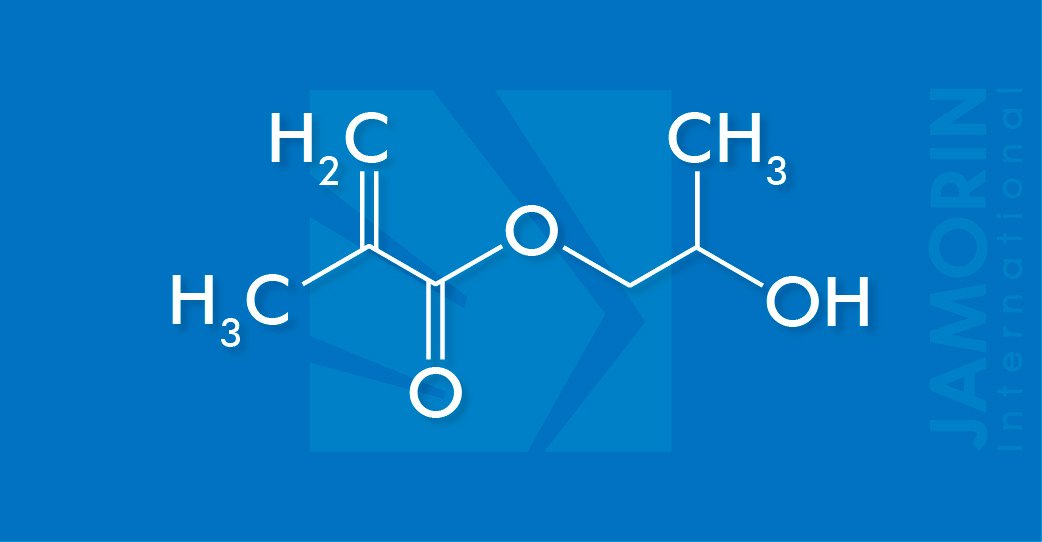

2-Hydroxypropyl Methacrylate (2-HPMA)

2-Hydroxypropyl Methacrylate (2-HPMA) is an ester of Methacrylic acid and is used as a raw material component in the synthesis of polymers. 2-Hydroxypropyl Methacrylate (2-HPMA) is a functional hydrophobic hydroxy monomer consisting of a methacrylate group with a characteristic high reactivity and a cyclic hydrophobic group. 2-Hydroxypropyl Methacrylate (2-HPMA) forms a homopolymer and copolymer. Copolymers of 2-Hydroxypropyl Methacrylate (2-HPMA) can be prepared with (meth)acrylic acid and its salts, amides, and esters, as well as with (meth)acrylates, acrylonitrile, maleic acid esters, vinyl acetate, vinyl chloride, vinylidene chloride, styrene, butadiene, and other monomers.

2-Hydroxypropyl Methacrylate (2-HPMA) easily entering into the reaction of accession with a wide range of organic and inorganic substances, is used to synthesize organic low molecular weight substances.

Product Type: Methacrylate Monomer

Features & Benefits:

- Chemical resistance

- Hydraulic stability

- Hydrophobicity

- Flexibility

- Adhesion

- Shock resistance

- Weather resistance

Applications areas:

- 2-Hydroxypropyl Methacrylate (2-HPMA) used in the preparation of solid and emulsion polymers, acrylic dispersions in combination with other (meth) acrylates, which are used in various industries, especially for textile coatings and dressings. 2-Hydroxypropyl Methacrylate (2-HPMA) is widely used in the production of acrylic polyols for automotive components, refurbishment coatings, and industrial coatings. 2-Hydroxypropyl methacrylate (2-HPMA) is also used as a comonomer in styrene-based unsaturated polyesters, PMMA-based acrylic resins, and vinyl ester formulations in anchor bolts and chemical anchors. 2-Hydroxypropyl methacrylate (2-HPMA) is particularly useful as a hydrophobic hydroxy monomer in the manufacture of sealants for vacuum impregnation of cast aluminum components. 2-Hydroxypropyl Methacrylate (2-HPMA) is also widely used in the production of flexible UV-curable photopolymer printing plates.

It is applied in the production of:

- Automotive coatings

- Architectural coatings

- Industrial coatings

- Plastics

- Hygiene products

- Adhesives & sealants

- Textile finishes

- Modifications

- Photosensitive materials

- Additives for oil production and transportation

Chemical Properties:

-

Puritymin. 97.0%

-

Acid Valuemax. 0.2%

-

Water contentmax. 0.15%

-

Color APHAmax. 30

Physical Properties:

-

Appearanceclear

-

Physical formliquid

-

Odor-

-

Molecular weight144.17 g/mol

-

Polymer Tg-

-

Tg-

-

Density1,029 g/cm3 at 20°C

-

Boiling Point209°C(5mmHg)

-

Freezing Point-58°C

-

Flash point104°C

-

Melting Point-58°

-

Viscosity8.9 mPa · s at 20°C

-

Vapor Point0.05 mm Hg at 20°C

-

pH-

To prevent polymerization, 2-Hydroxypropyl Methacrylate (2-HPMA) should always be stored in air, and never under inert gases. For the stabilizer to work effectively, oxygen is required. It must contain a stabilizer. Storage temperature should not exceed 35 °C. Under these conditions, the storage stability of one year can be expected. To minimize the likelihood of congestion, the storage procedure should strictly follow the principle of “first come, first come”. For a long shelf life of more than 4 weeks, it is advisable to replenish the oxygen content. Over time, the content of ethylene glycol diacrylate slowly increases. If this component is relevant to your process, 2-Hydroxypropyl Methacrylate (2-HPMA) should be used within 12 months of receipt. The preferred material for tanks and pipes is stainless steel. Carbon steel is also used, although rust formation may occur, which will lead to a problem with product quality (color). Iron (III) -ion has been shown to be a weak initiator of polymerization. If carbon steel is to be used, special treatment should be used to prepare the tank for use. Storage tanks, pumps, and pipes must be earthed.

Storage & Handling:

To prevent polymerization, 2-Hydroxypropyl Methacrylate (2-HPMA) should always be stored in air, and never under inert gases. For the stabilizer to work effectively, oxygen is required. It must contain a stabilizer. Storage temperature should not exceed 35 °C. Under these conditions, the storage stability of one year can be expected. To minimize the likelihood of congestion, the storage procedure should strictly follow the principle of “first come, first come”. For a long shelf life of more than 4 weeks, it is advisable to replenish the oxygen content. Over time, the content of ethylene glycol diacrylate slowly increases. If this component is relevant to your process, 2-Hydroxypropyl Methacrylate (2-HPMA) should be used within 12 months of receipt. The preferred material for tanks and pipes is stainless steel. Carbon steel is also used, although rust formation may occur, which will lead to a problem with product quality (color). Iron (III) -ion has been shown to be a weak initiator of polymerization. If carbon steel is to be used, special treatment should be used to prepare the tank for use. Storage tanks, pumps, and pipes must be earthed.

2-Hydroxypropyl Methacrylate (2-HPMA) is a combustible substance. With intense healing, it forms explosive vapors with air. Vapors are heavier than air and may spread along with floors. In the case of fire formation of harmful gaseous products is possible. Contact with skin may cause an allergic reaction. When working with 2-Hydroxypropyl Methacrylate (2-HPMA), sanitary rules for organizing technological processes and hygienic requirements for production equipment must be strictly observed. All types of work with 2-HPMA should be carried out in rooms equipped with general supply and exhaust ventilation. It is not allowed to carry out work in these rooms using an open fire. Those working with 2-Hydroxypropyl Methacrylate (2-HPMA) should be provided with special clothing and personal protective equipment. In case of fire, it is necessary to use fire extinguishers OP-5, OVP-100 koshma, sand, asbestos cloth. 2-Hydroxypropyl Methacrylate (2-HPMA) spilled on solid soil should be covered with sand.

The data presented here are based on current knowledge and experience. Given the many factors that can affect the processing and use of the product, these data do not free consumers from the need to conduct their own tests and samples. Also, these data do not imply a guarantee of any specific properties or suitability of the product for a particular application. Any descriptions, drawings, photographs, data, ratios, weights, etc. presented here. subject to change without prior notice and do not constitute the contractual quality of the product. The end-user of the product is required to comply with all property rights and existing laws, as well as legal standards.